| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Brand Name : Bicheng

Certification : UL, ISO9001, IATF16949

Place of Origin : CHINA

MOQ : 1PCS

Price : USD9.99-99.99/PCS

Payment Terms : T/T

Supply Ability : 5000PCS per month

Delivery Time : 8-9 working days

Packaging Details : Vacuum bags+Cartons

PCB Material : TC600 - 1.524 mm (60mil)

Layer Count : 2-layer

PCB Size : 76mm x 57 mm=4Types = 4PCS, +/- 0.15mm

PCB Thickness : 1.6mm

Copper Weight : 1oz (1.4 mils) inner/outer layers

Surface Finish : Immersion gold

Solder Mask : No

Silkscreen : No

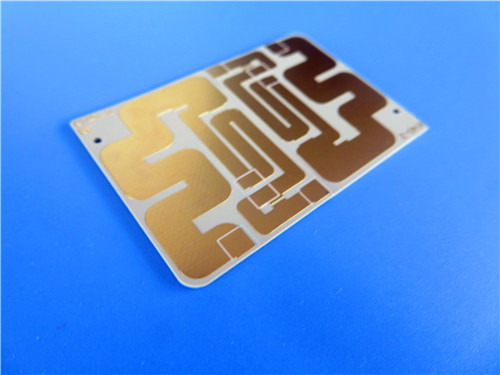

Introducing our newly shipped TC600 Double-Sided PCB, engineered to meet the high-performance demands of modern electronic applications. Utilizing advanced TC600 laminates, this PCB offers exceptional thermal management and reliability, making it ideal for a variety of high-frequency and high-power applications.

Premium Base Material: TC600

This TC600 PCB is constructed using Rogers TC600 laminates, which consist of PTFE, thermally conductive ceramic fillers, and woven glass reinforcement. This advanced composite material is designed to enhance heat transfer and minimize dielectric loss, resulting in improved performance in high-frequency applications.

Layer Count and Dimensions

This PCB features a double-sided construction, which maximizes functionality while optimizing space. With dimensions of 76mm x 57mm (±0.15mm) and a finished thickness of 1.6mm, this PCB is versatile enough for various electronic devices.

Trace and Hole Specifications

The board is engineered with a minimum trace and space of 4/5 mils, ensuring precise circuit layouts. A minimum hole size of 0.3mm is maintained, with no blind vias, ensuring structural integrity and reliability.

Copper Layers and Surface Finish

This PCB features two copper layers, each comprising 18 μm of copper and an additional 17 μm of plating. The immersion gold surface finish enhances solderability and provides excellent protection against oxidation.

Quality Assurance

Each board undergoes rigorous 100% electrical testing prior to shipment, ensuring compliance with IPC-Class-2 quality standards and guaranteeing reliability for various applications.

| Property | Unit | Value | Test Method |

| 1. Electrical Properties | |||

| Dielectric Constant (may vary by thickness) | |||

| @1.8 MHz | - | 6.15 | Resonant Cavity |

| @10 GHz | - | 6.15 | IPC TM-650 2.5.5.5 |

| Dissipation Factor | |||

| @1.8 GHz | - | 0.0017 | Resonant Cavity |

| @10 GHz | - | 0.002 | IPC TM-650 2.5.5.5 |

| Temperature Coefficient of Dielectric | - | ||

| TCεr @ 10 GHz (-40-150°C) | ppm/ºC | -75 | IPC TM-650 2.5.5.5 |

| Volume Resistivity | |||

| C96/35/90 | MΩ-cm | 1.6x109 | IPC TM-650 2.5.17.1 |

| E24/125 | MΩ-cm | 2.4x108 | IPC TM-650 2.5.17.1 |

| Surface Resistivity | |||

| C96/35/90 | MΩ | 3.1x109 | IPC TM-650 2.5.17.1 |

| E24/125 | MΩ | 9.0x108 | IPC TM-650 2.5.17.1 |

| Electrical Strength | Volts/mil (kV/mm) | 850 (34) | IPC TM-650 2.5.6.2 |

| Dielectric Breakdown | kV | 62 | IPC TM-650 2.5.6 |

| Arc Resistance | sec | >240 | IPC TM-650 2.5.1 |

| 2. Thermal Properties | |||

| Decomposition Temperature (Td) | |||

| Initial | °C | 512 | IPC TM-650 2.4.24.6 |

| 5% | °C | 572 | IPC TM-650 2.4.24.6 |

| T260 | min | >60 | IPC TM-650 2.4.24.1 |

| T288 | min | >60 | IPC TM-650 2.4.24.1 |

| T300 | min | >60 | IPC TM-650 2.4.24.1 |

| Thermal Expansion, CTE (x,y) 50-150ºC | ppm/ºC | 9, 9 | IPC TM-650 2.4.41 |

| Thermal Expansion, CTE (z) 50-150ºC | ppm/ºC | 35 | IPC TM-650 2.4.24 |

| % z-axis Expansion (50-260ºC) | % | 1.5 | IPC TM-650 2.4.24 |

| 3. Mechanical Properties | |||

| Peel Strength to Copper (1 oz/35 micron) | |||

| After Thermal Stress | lb/in (N/mm) | 10 (1.8) | IPC TM-650 2.4.8 |

| At Elevated Temperatures (150ºC) | lb/in (N/mm) | 10 (1.8) | IPC TM-650 2.4.8.2 |

| After Process Solutions | lb/in (N/mm) | 9 (1.6) | IPC TM-650 2.4.8 |

| Young’s Modulus | kpsi (MPa) | 280 (1930) | IPC TM-650 2.4.18.3 |

| Flexural Strength (Machine/Cross) | kpsi (MPa) | 9.60/9.30 (66/64) | IPC TM-650 2.4.4 |

| Tensile Strength (Machine/Cross) | kpsi (MPa) | 5.0/4.30 (34/30) | IPC TM-650 2.4.18.3 |

| Compressive Modulus | kpsi (MPa) | ASTM D-3410 | |

| Poisson’s Ratio | - | ASTM D-3039 | |

| 4. Physical Properties | |||

| Water Absorption | % | 0.02 | IPC TM-650 2.6.2.1 |

| Density, ambient 23ºC | g/cm3 | 2.9 | ASTM D792 Method A |

| Thermal Conductivity (z-axis) | W/mK | 1.1 | ASTM E1461 |

| Thermal Conductivity (x, y) | W/mK | 1.4 | ASTM E1461 |

| Specific Heat | J/gK | 0.94 | ASTM E1461 |

| Flammability | class | V0 | UL-94 |

| NASA Outgassing, 125ºC, ≤10-6 torr | |||

| Total Mass Loss | % | 0.02 | NASA SP-R-0022A |

| Collected Volatiles | % | 0 | NASA SP-R-0022A |

| Water Vapor Recovered | % | 0 | NASA SP-R-0022A |

Technical Features

Dielectric Properties

The TC600 laminate exhibits a dielectric constant (Dk) of 6.15 at both 1.8MHz and 10GHz. This property is essential for reducing signal loss and enhancing overall circuit performance, particularly in RF applications.

Thermal Management

With a thermal conductivity of 1.1 W/mK, the TC600 PCB excels in heat dissipation, making it ideal for high-power applications. The low dissipation factor—0.0017 at 1.8GHz and 0.0020 at 10GHz—further contributes to efficient thermal management.

Stability Across Temperatures

The TC600 PCB maintains a stable Dk across a wide temperature range of -40°C to 140°C, with a low coefficient of thermal expansion (CTE) of 9 ppm/°C in the X/Y axes and 35 ppm/°C in the Z axis. This stability is crucial for minimizing stress on solder joints, enhancing the longevity and reliability of the PCB.

Benefits of the TC600 PCB

1. Size Reduction: TC600 PCB enables a smaller footprint compared to lower Dk substrates, allowing for more compact designs.

2. Enhanced Efficiency: By reducing heat generation through minimized transmission line losses, the PCB improves overall efficiency, crucial for high-performance applications.

3. Increased Reliability: Improved processing capabilities and CTE matching ensure low-stress solder joints, making the PCB highly reliable in demanding environments.

Applications

TC600 PCB is versatile and suitable for a range of applications, including:

- Power Amplifiers: Essential for maximizing signal strength in communication devices.

- Filters and Couplers: Used in RF applications to manage frequency signals effectively.

- Microwave Combiners and Power Dividers: Critical for efficient signal processing in advanced communication systems, particularly in avionics.

- Small Footprint Antennas: Ideal for applications requiring compact designs, such as GPS and hand-held RFID reader antennas.

- Digital Audio Broadcasting (DAB) Antennas: Perfect for satellite radio applications, ensuring high-quality audio transmission.

Conclusion

TC600 Double-Sided PCB represents a significant advancement in PCB technology, designed to meet the rigorous demands of modern electronics. With its exceptional materials, meticulous construction, and robust testing, this PCB is poised to elevate the standards of performance in various high-frequency applications.

Engineers and manufacturers can trust the TC600 PCB to deliver reliability, efficiency, and innovation, paving the way for the next generation of electronic devices.

|

|

2 Layer PCB Built On TC600 Laminate 60mil Immersion Gold Finish Images |